Seems like no-brainer. You have something that needs making and they make stuff. All that’s left is to sign on the dotted line, right?

Seems like no-brainer. You have something that needs making and they make stuff. All that’s left is to sign on the dotted line, right?

Maybe. Maybe not.

Here are a few of the reasons you may not be getting the answers you want from the manufacturer you approach with your new product.

1) They are not be the right kind of manufacturer for your product or your current design status.

Have you done your homework? Do you understand what process should be used to prototype your product? Will it be the same process to manufacture in production volumes?

If not, then you may be sitting in front of the wrong people or sitting in front of the right people, just too soon for them to be able to help.

Let’s say you know that you want an injection molded part, but first you need prototypes and this manufacturer only does high volume production work…..no prototyping. You likely need a rapid prototype supplier first.

2) You don’t have enough information for the manufacturer to make the part.

This is a story I hear often from both manufacturing partners and the clients they have referred.

“I went to so and so with my idea for the product, asking for a quote…but they said I need to have it engineered first.”

Think of the manufacturer as a chef, you go in and ask them to make your mother’s secret meatloaf. They may know about cooking, but to make something very specific they will need a recipe.

The recipe your manufacturer wants is in the form of 3D models and 2D drawings that tell them what to make. They will often collaborate….but very rarely take on the burden of designing the product for you.

3) You aren’t financially prepared to move forward with the process that you want to use and the vendor isn’t looking to partner with a start-up.

In my experience the number of people looking to get a product made for free by offering the vendor a piece of the business is vast compared to the number of vendors open to that arrangement.

Not all processes are expensive to tool. You may prototype one way and move to another process after proving out your concept, market and finding your customers.

Maybe you don’t start with the $30K multi-cavity steel tool out the gate, but opt for an aluminum prototype tool to make a few thousand parts to get you in business…..then start saving the money to invest in your business growth down the road.

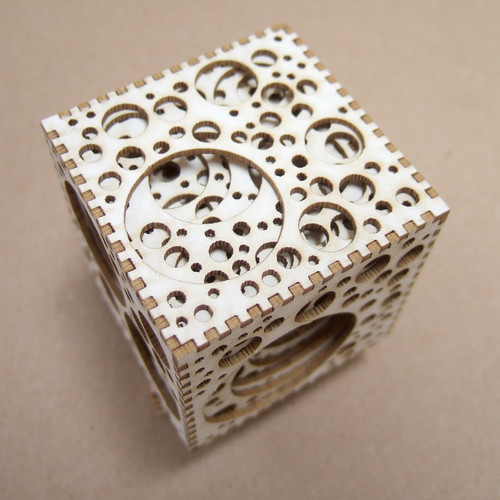

(photo: cc licensed ( BY ) flickr photo shared by

Leave a Reply